INVESTMENT CASTING – YOUR ADDED VALUE

To provide you with the best possible solutions, we’ve developed a broad spectrum of services, drawing on years of expertise in investment casting, machining, and assembly. In the following pages, you’ll discover insights into our PROCAST ADVISORS world, featuring a range of casting materials, lightweight construction solutions, complex part geometries, and other intriguing topics.

Investment Casting Process

Comprehensive support to resolve casting producibility issues of the two essential methods in investment casting: atmospheric casting and vacuum casting, casting latent defects, Design to Manufacturability, yield improvement, fixed process/substantiation, modeling, quality, and post-cast Nadcap special process audits. We can provide problem-solving solutions from part and gate design to best metal practices and metallurgical/NDT. Process optimization and scrap reduction are our specialties.

Casting Capability

Whether you’re new to the casting business, or have years of experience, we can help, whatever your challenge is.

Our team has good experience working in casting foundries, specializing in investment castings. We’ve also spent decades in component part design, materials & process engineering. This makes us the ideal choice for technical support like concurrent design engineering and manufacture, rapid prototyping, and manufacture process optimization.

- Some of the engineering services we have provided for clients include:

- CAD modelling

- 3D wax/ceramic printing

- Dimensional studies

- Gating development

- Innovative casting process design

- NDT test requirements definition and review

- Metallurgical test requirements definition and review

We have development experience from initiation to closure for more than 200-part number Vacuum and Air melt such as:

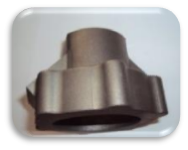

- Swirlers, Mixers, Cyclones, and Associates: Alloys Co 6, Co 25, Co 31, Mar-M509, Hast-X, Rene220 for programs Leap-1AC/1B, CFM56, CF6, GEnx, GE-9X, LM2500, LM6000 V2500, AE3007.

- Flanges, Plates, Elbows, and Connectors: Alloys GTD222, Inco 615, Inco 718, Mar-M509 for programs all major commercial engine.

- Structural Airfoils: Alloys Inco 738, Co 6, FSX414, Mar-M509, Hast-X, Mar-M247, Rene 77, 15-5PH for programs industrial & Commercial engines.

- LPT Shroud Segments: Alloys Inco 738, Rene 108 for Programs GE9X.

Fairings: Alloys Rene 108 for Programs Leap-1A, Leap-1B, Leap-1C, LM2500.

Concept Ideation

With our extensive executive-level experience, and expertise in advanced technologies and patent development, we are able to develop technical solutions that make business sense.

Our team is proficient in varying areas of concept & ideation, including :

- Patent inventions

- Factory, equipment, and manufacturing process design

- Component part design and modeling, including gating

- Substantiation and qualification test plans

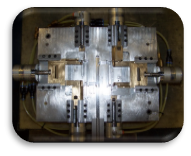

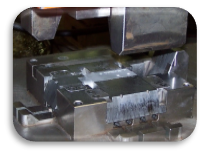

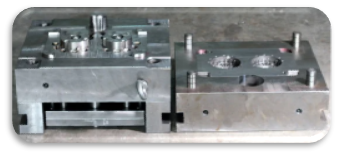

Tool Manufacturing

We are proud to offer you our advanced manufacturer and designer tooling. The company provides wax and ceramic mold tools and gauging, wax setters, fixtures for gate witness removal, machine fixtures for precision machining of castings, CNC, and EDM, delivering a one-stop solution for aerospace and industrial gas turbine engine engineering problems. We also offer rapid prototyping and rapid tooling. We provide guidance to ensure parts are designed for optimum performance and efficient assembly. Our advanced straightening fixtures and techniques can be used in hot or cold temperatures, depending on the metal alloys. Our designers and toolmakers will work directly with you to move your concept drawings to the production stage by combining cutting-edge technology with professional technical expertise.